AerO Coated Fabrics which does Extrusion Coating and Film Extrusion was founded by 2 thermoplastics experts: Rinus Aerts who is a chemist, TPO / PVC technician and R&D expert with 40 years’ experience, and Fred Roffelsen (AeRo), entrepreneur in the Plastic Industry.

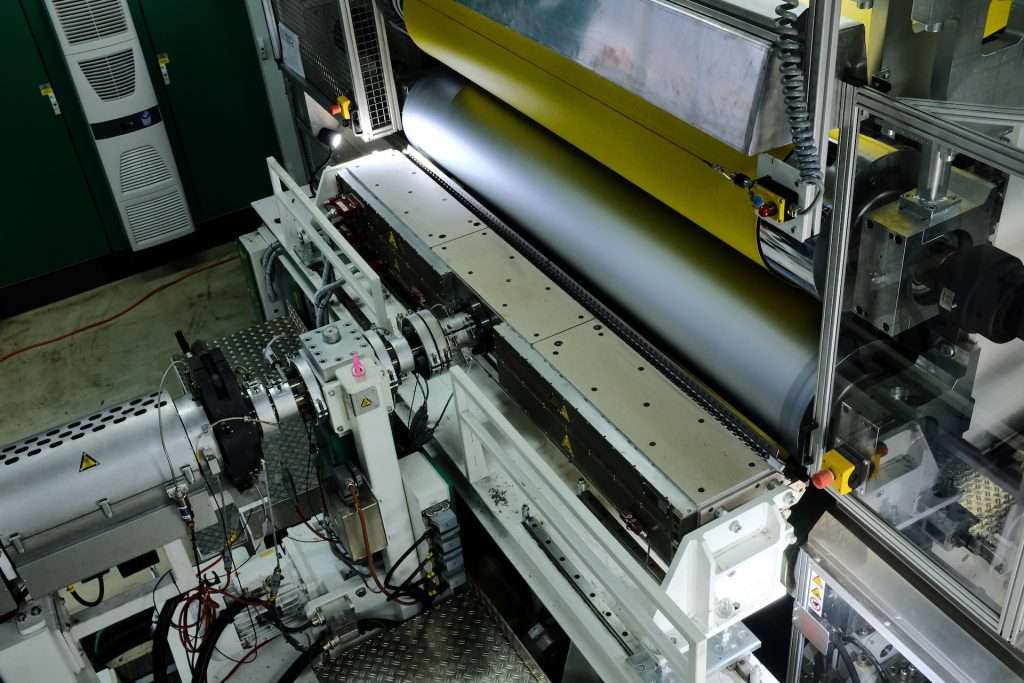

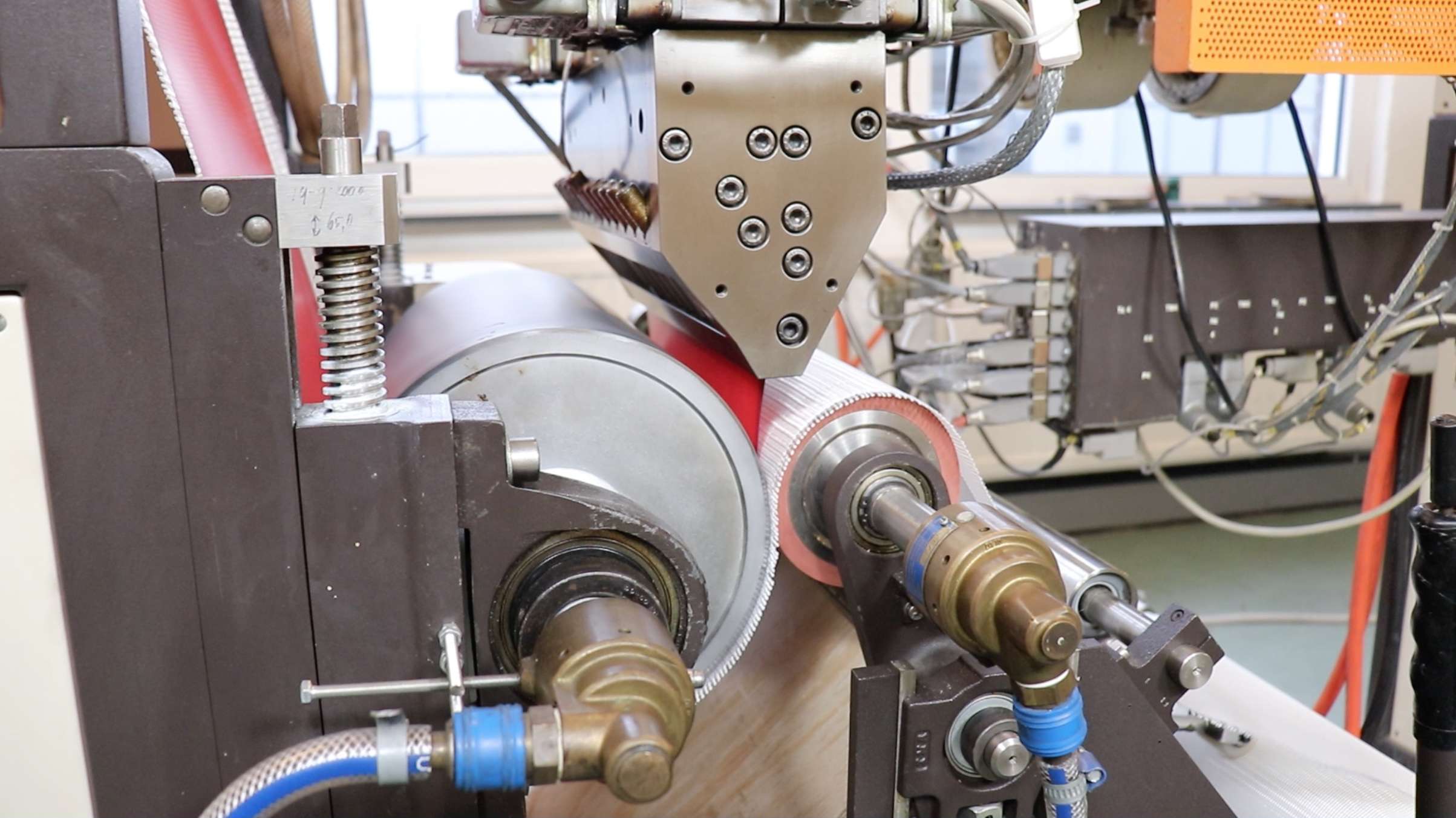

Adding this with the latest technology of a brand new, state of the art 2.200 mm wide extrusion coating calandar in 2018 and and expanded and updated during the years there, with experienced production staff, familiar with the finesses and details of extrusion coating equipment, allowed us within 3 years “to become the quality coating specialist” in Western Europe.

In March 2021 Aero Coated Fabric was purchased by CaPlast Kunststoffverarbeitungs GmbH and Fred Roffelesen then decided to retire. In April 2023, CaPlast was purchased together with Aero Caoted Fabrics by the Kingspan Group. Aero will continue to focus on R&D and special prodcution for its customers as before. We are currently busy expanding our production site and will move to a new location that is more than twice as large on the adjacent business park in 2025. The ambition for 2026 is to run a second extrusion coating calandar machine.

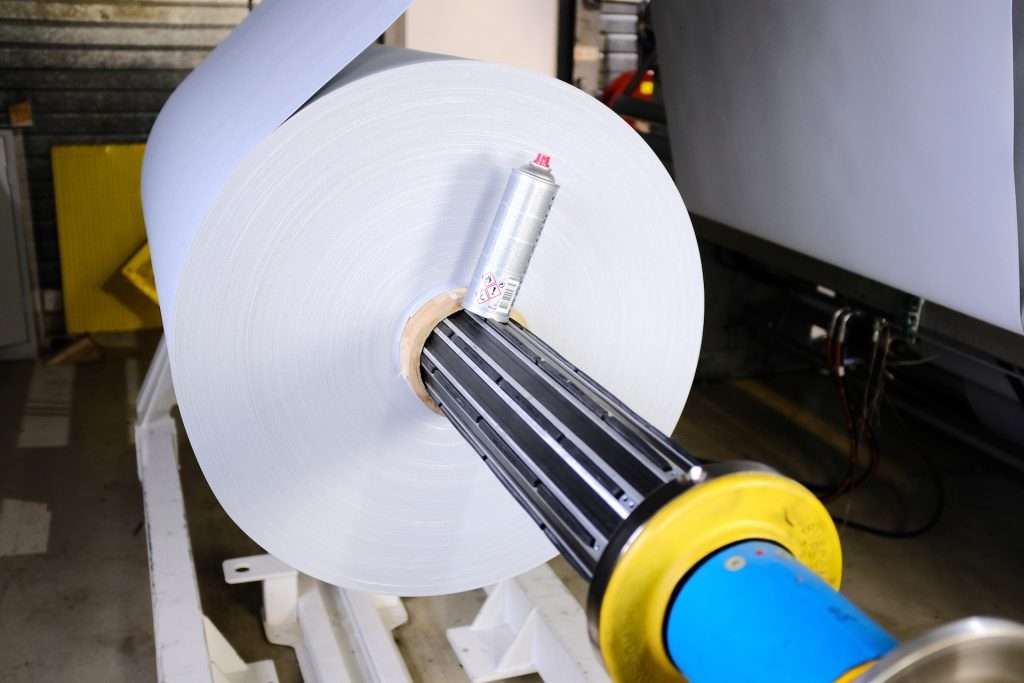

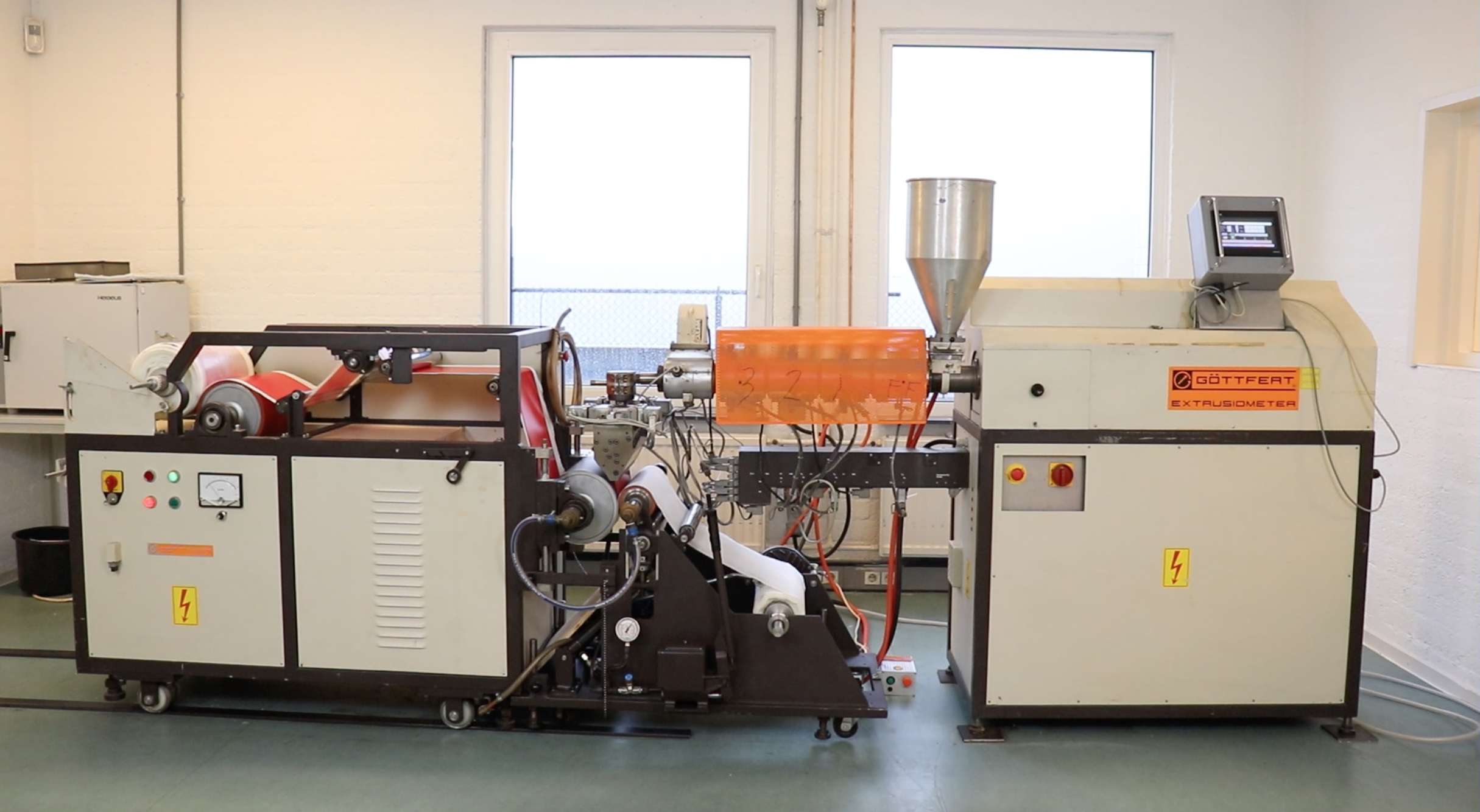

Supported by our own laboratory extruder, financial capacity, and specialized R&D support of CaPlast, Aero Coated Fabrics is birthplace of new coating combinations of product solutions and market developments.

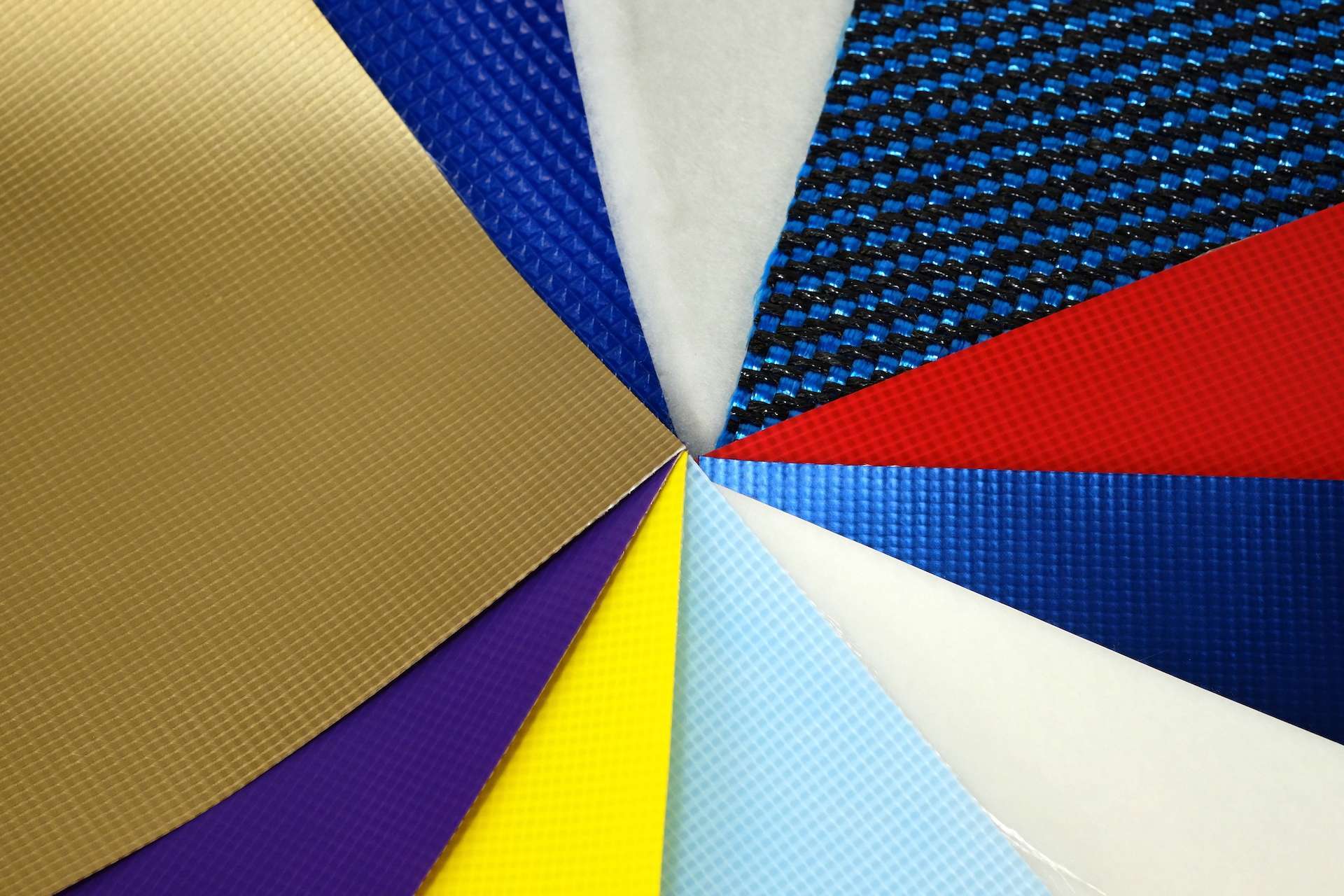

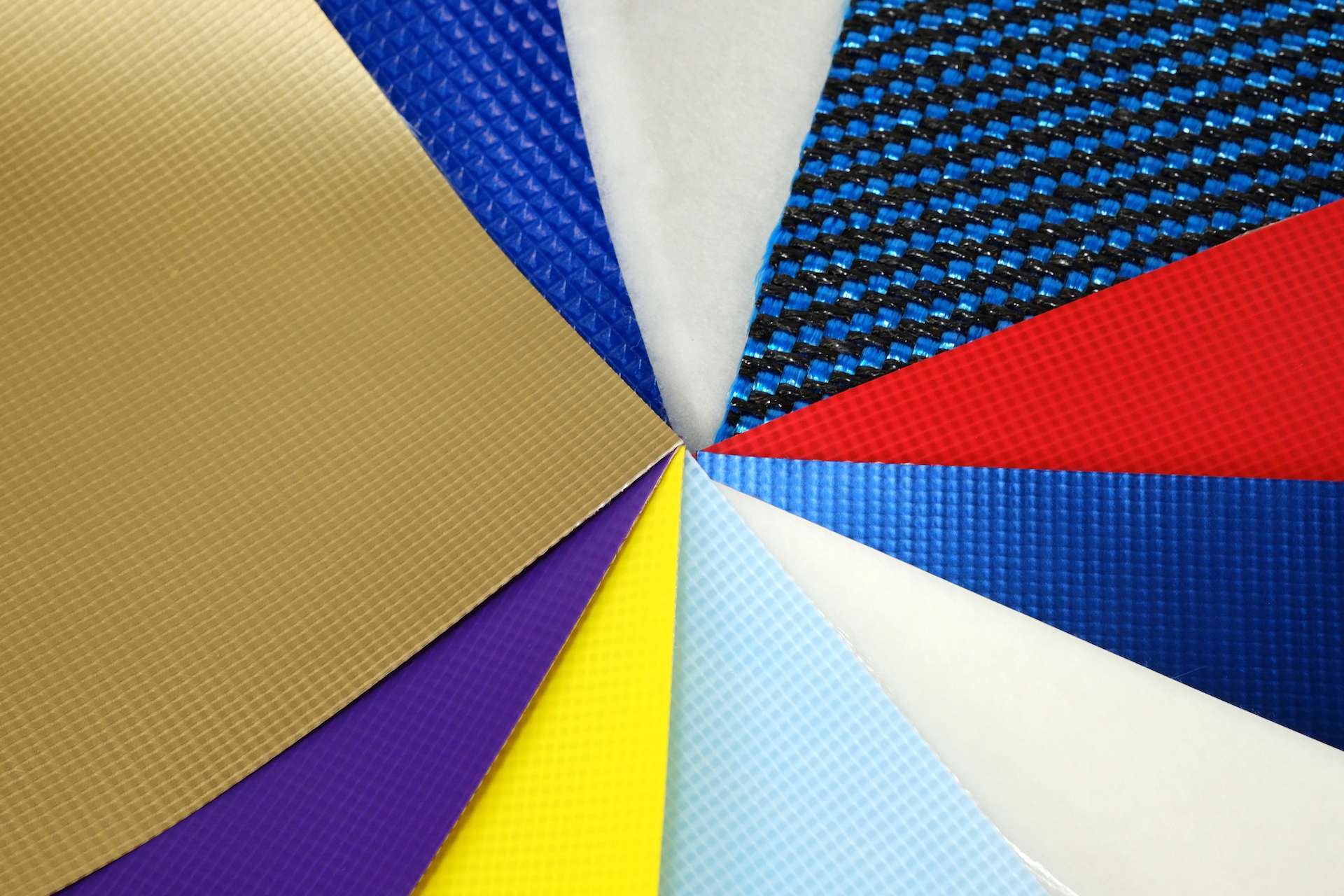

We produce high end PVC and non PVC coated (technical textile) products for: dancing floors, flexible acoustic separating curtains, conveyor belts, sewage pipe renovation CIPP, concrete silo protection, pool covers, cow mattresses, solar film, rubber packings and many more coating solutions. All of which is specially developed for specific needs. Our ambition and policy guides us to support society with better solutions using recyclable materials, if possible free from plasticizers and more secure in application using flame retardant components, in combination with UV stable solutions.

Altogether, you could describe Aero Coated Fabrics as being: modern, ambitious, R&D focused, capable of offering flexibility in manufacturing Extrusion Coating and Film Extrusion, short delivery time, smaller production runs, excellent service, and use of our „expertise and experience“ to deliver the best product. Our internal motto; ‘we do it together’

That is why we dare to say: “We solve your challenge”

Contact

AerO Coated Fabrics B.V., Simon de Cockstraat 18, 5048 AW Tilburg (NL)

+31 (0)132077877

VAT: NL858016436B01

COC: 69798133

Products

Manufacturing

AerO Coated Fabrics, offers a full service toll manufacturing technical textiles Extrusion Coating and Film Extrusion. With the latest state of the art extrusion calendar, laboratory and testing equipment we offer a complete service to develop new products and improve existing products.

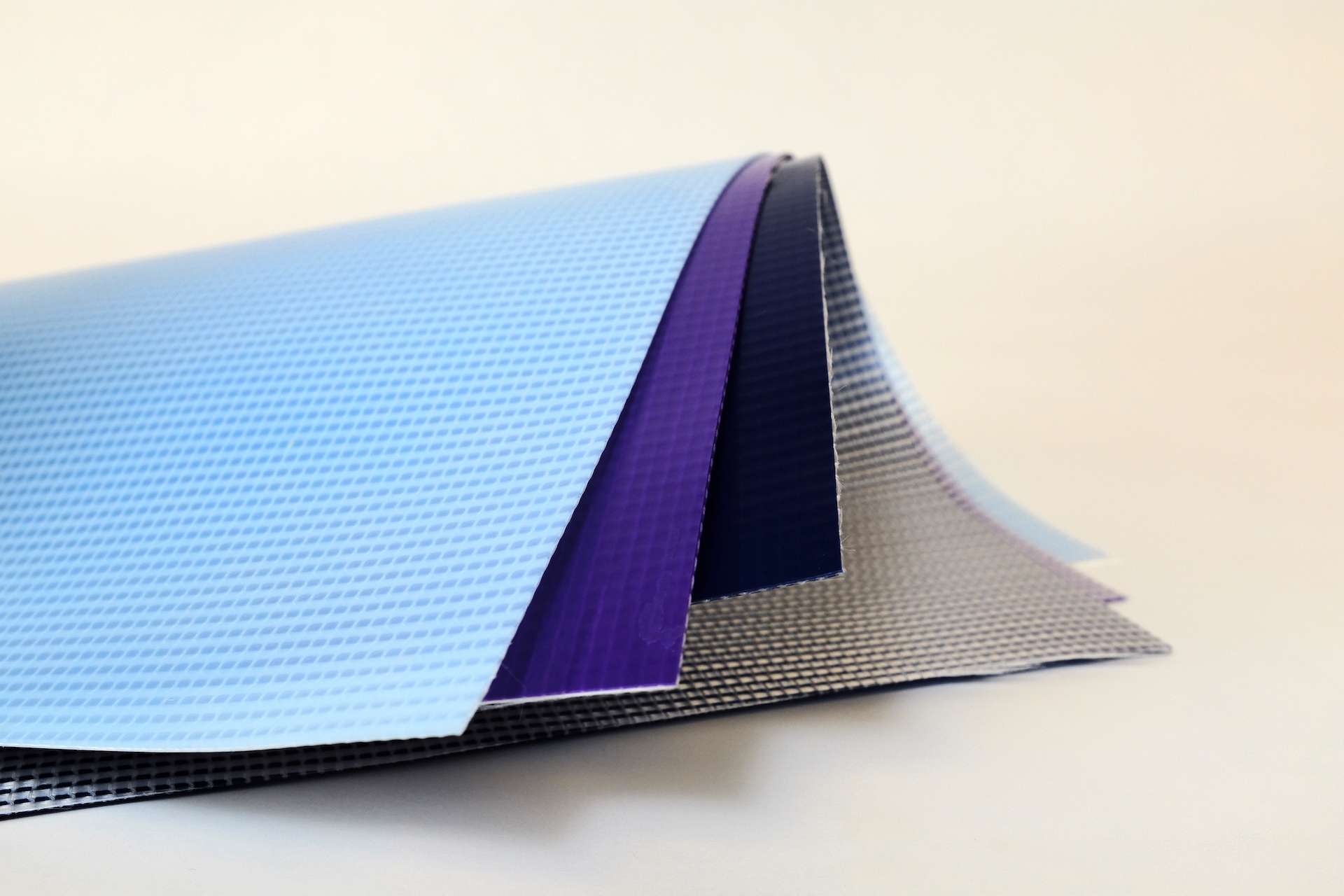

Whether it’s a manufacturer or end user the range of polymers that AerO Coated Fabrics can access in combination with almost any type of fabric / technical textiles, woven or non-woven, makes AerO Coated Fabrics your perfect partner for manufacturing and development.

With our state of the art equipment we can offer the following production services

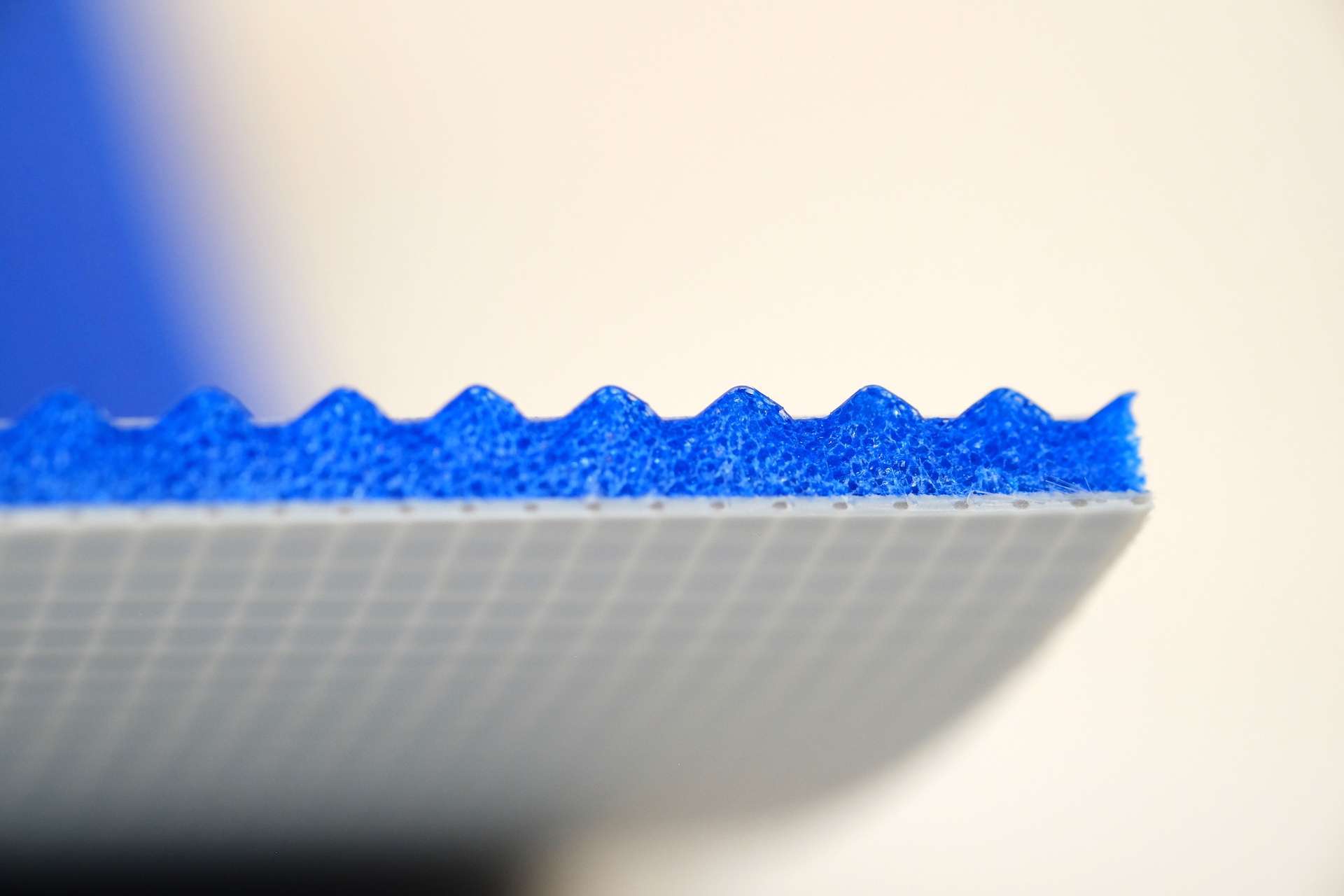

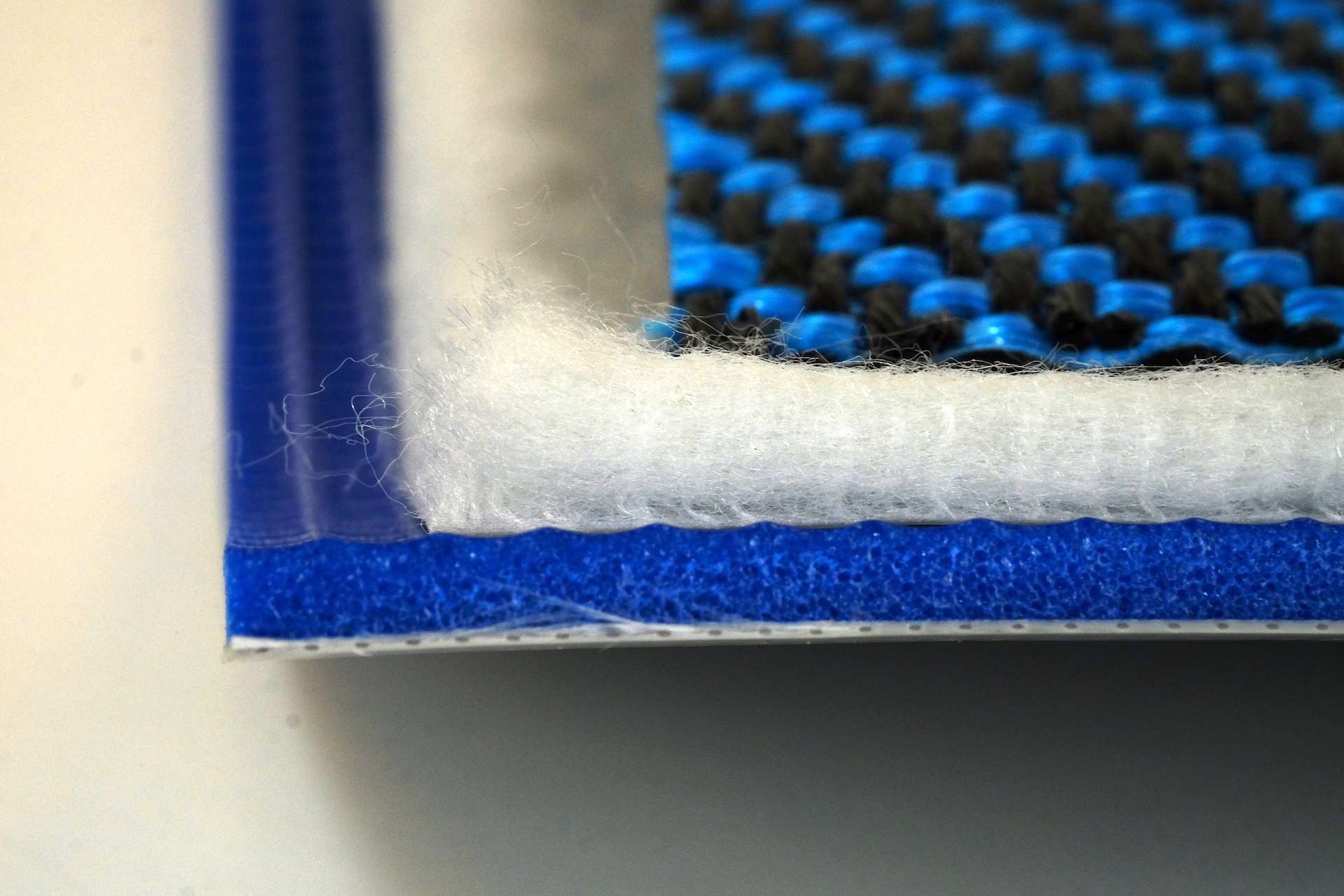

This extrusion coating is a process to direct coat a film onto a fabric / technical textiles or non-woven. The coating adds special proporties such as waterproofing, flame resistant, abrasion resistance, antislip, antistatic and printable. The coating also offers protection against wind, water, cold and chemicals.

With our latest state of the art extrusion equipment we are able to process all sorts of polymers:

TPU (Thermoplastic Polyurethane), PE (PolyEthylene), PP (PolyPropylene), TPE (Thermoplastic Elastomer), SBR (Styrene Butadiene Rubber), PVC-P (Plasticized Poly Vinyl Chloride), EVA (EthylVinylAcetate) and other polymers and reforming it into a film or onto a fabric / technical textiles

.

The production line is equipped with a gravimetric hopper dosing and mixing system. Up to 4 additives can be added to the compound during production such as UV stabilizers, Foaming Agents, Color Master batches, Anti-block, impact modifiers, flame retardants.

The production line is equipped with a 3 roller calendar. The rolls are interchangeable and include the facility to offer inline embossing of different structures and designs. Standard embossings are gloss finish, matt finish and a leather embossing.

Besides the embossing rollers we can also direct extrude onto an embossed release liner making the choice of embossing infinite.

Inline slitting, side trimming plus additional cuts upon request.

For perfect shipping AerO Coated Fabrics offers packaging according to clients specifications. From Jumbo rolls into size rolls all packed according to customer demands.

Production

The machinery is ideal for top-quality surface extrusion coated finishes technical textiles. ‘Extrusion Coating and Film Extrusion’. Because it allows for custom products composition and thicknesses, it is a preferred method for producing sewage liners (CIPP), cow mattresses, swimming pool liners and covers, concrete protection, supported and unsupported films/foils, sports hall divider curtains, sliding doors, roofing membranes, monolithic conveyor belts, medical mattresses, sport matts, dancing floors.

Benefits are customizable thicknesses, increase durability, water resistant, reliable quality and consistency, monolayer or Co-Extrusion technologies AerO Coated Fabrics offers their customers a combination of experience, innovation and flexibility as well as small order quantities.

Our coating extrusion capabilities:

Extrusion Coating on woven, non-woven, knitted PET, PP, PE, Nylon, Cotton, 3D, Spun, PES, Glass Fiber-fabrics.

PP, PE, LDPE, Bio-based polymers, TPU, HDPE, LLDPE, EVA, PVC-P

Gravimetric Hopper with 4 feeding stations to add color master batches, and additional properties such as antiblock, foaming agents, UV stabilizers, adhesion promoters, flame retardant, etc.

Some polymers exhibit a level of polarity and therefore is capable of absorbing a certain amount of moisture from the atmosphere. AerO Coated Fabrics has the equipment to dry polymers with such properties prior to processing.

Embossing: In-line with Standard Structures matt finish, high gloss finish, and leather look any other desired structure can be customized.

Development

AerO Coated Fabrics offers the option to work with you from development of new combination of fabrics and coatings to certifications of Extrusion Coating and Film Extrusion. Generally speaking we are co-operating to develop solutions for new applications and improvements of existing products.

When the requirements of the customer are clear we will develop the new product in close co-operation with the customer.

R&D and prototyping projects demand a customer specific approach. At AerO Coated Fabrics we use phases to manage the project from initial request to commercial availability according to NEN- ISO 9001 regulation.

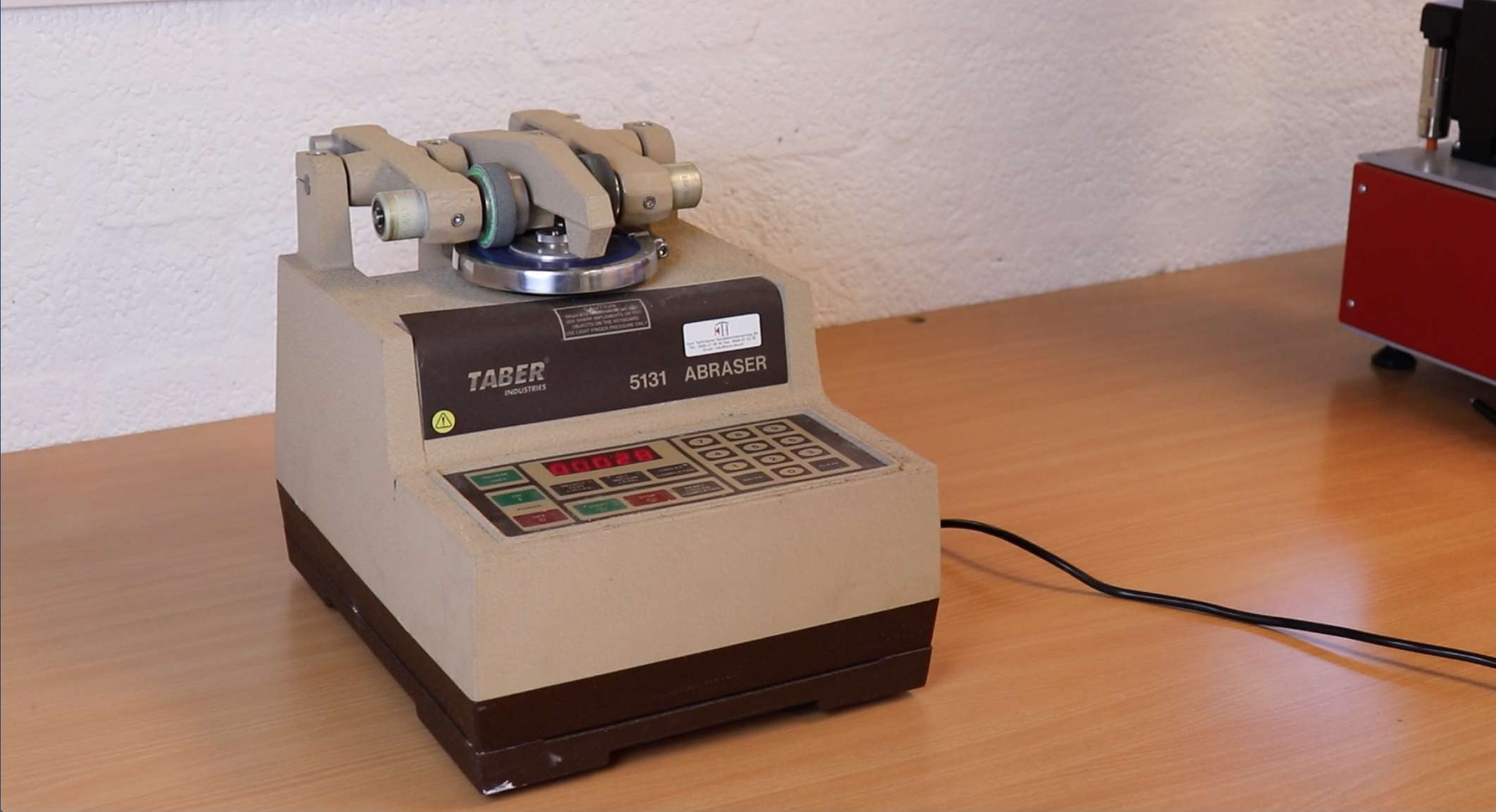

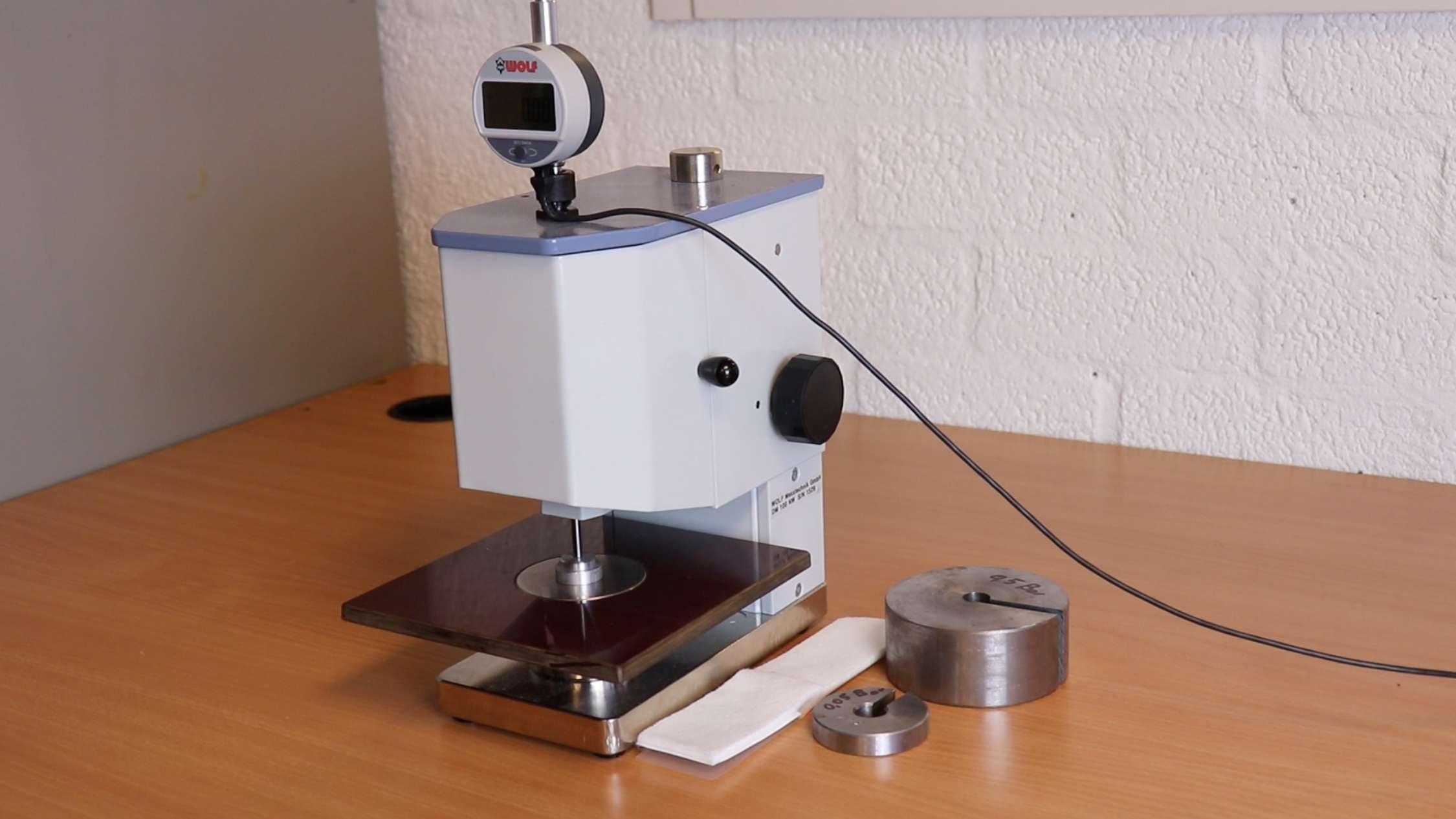

The in-house laboratory is equipped for controlling mechanical properties like tensile strength, elongation, adhesion, tear strength, resistance to abrasion and permeability.

Sustainability

Solvent-free

AerO Coated Fabrics extrusion coating is a clean manufacturing process, no liquids are used and all raw materials are in granulate form making it impossible to contaminate the environment.

New Developments

The industries processing thermoplastics are continuously striving to find better and cleaner raw materials and production methods. The extrusion coating line is highly energy and waste efficient. AerO Coated Fabrics is continuously following market developments and in close contact with their suppliers of raw materials.

Waste Management and Recycling

A closed loop system is in place for waste and off cuts for most manufactured coated fabrics and non-wovens. Reducing waste is key and already very effective due to the availability of the newest technologies.

Energy Control

With the machine commissioned in 2018 we make use energy efficient technologies based on the latest developments.

Certifications and certificates

With our knowledge we can guide our clients to find the best suited institutes for material testing of specific properties of Extrusion Coating and Film Extrusion. Testing of UV resistance, gas permeability, flammability, VOC testing, waterproofing, and wicking.

The duration and costs involved in the different phases are strongly depending on the requirements.